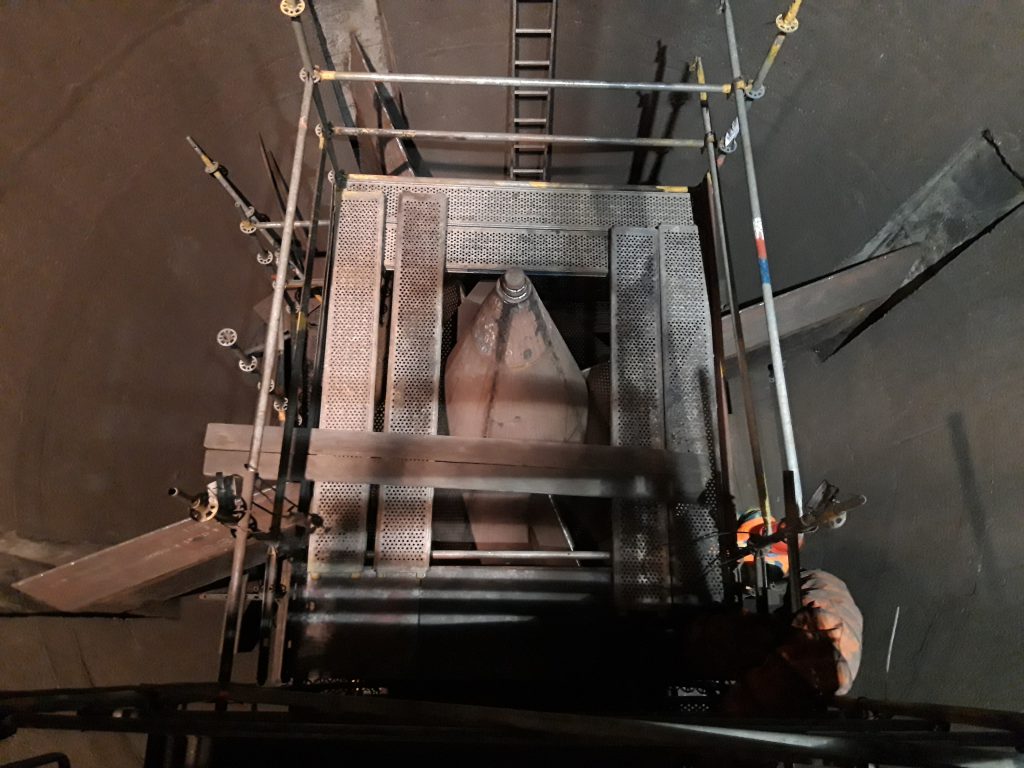

Reconstruction of the discharge device from slag silos A and B and installation of a new capacity downpipe of the emergency drainage of the slag silos.

The original metal pipeline is replaced by a new pipe drain made of AP line material, including a system for attachment to a concrete silo. The dimension (inner diameter) of the drain increased by 100 mm. The advantage of the newly installed pipe drain is greater absorption, excellent abrasion resistance, and surface slipperiness, which eliminates the formation of stickers and ensures the permeability of the entire transport route.

Furthermore, within the scope of the work, a complete reconstruction of the technology of slag discharge from A + B silos is performed, consisting of replacing the discharge arms of an extruder. The arms are newly supplied from Hardox 500 material with an active surface fitted with basalt paving, which can be easily changed according to the state of its current wear. An essential part of the reconstruction is the complete replacement of the inner cones, including the solution of the new construction of the supporting structure. Everything is made of Hardox 500 material. A composite anti-abrasive layer made of Rezotec material with a Kevlar insert and local surface lamination is applied to the working wall of the inner cones. The project aimed to increase the capacity of the slag transport technology, to ensure higher reliability of operation and service life of the equipment.