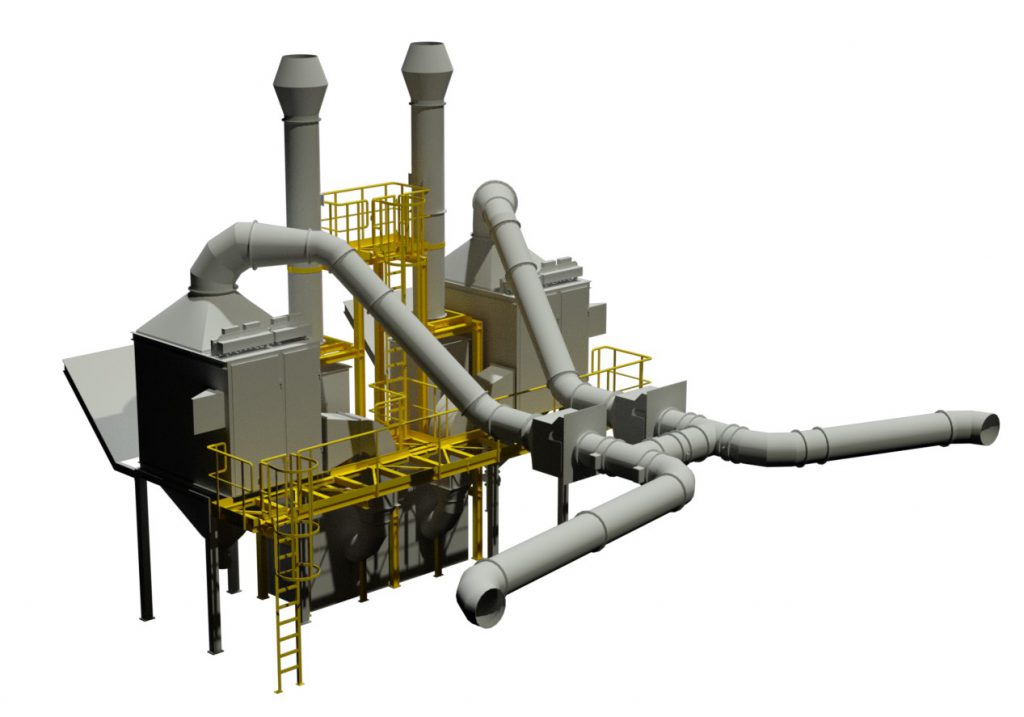

The subject of the work is the delivery of a complete solution for the extraction of transfer chute in the rough coal sorting plant of the Ledvice Coal Processing Plant – SD JSC. In total, it is the extraction of coal dust from 4 transfer chute and 2 belt conveyors.

The necessary suction power is provided by two FD622 filter units from the manufacturer NEDERMAN with a capacity of 2 x 21 000 Nm3 / hour, a total

of 42 000 Nm3/hour.

Each of the filter units is equipped with an anti explosive membrane and a deflector to direct the kinetic energy in the case of an explosion. To maintain the required noise level in the operating mode, the fans are equipped with silencers to meet the requirement for the noise limit of the 75 dBA per each device. The filters are delivered including the steel constructions of service platforms, which enables all service points accessible and allows periodic control measurements of the efficiency of the filters.

The pipeline route is made and delivered from steel pipes DN 250 – 560 mm and special fittings enabling the connection of explosion-proof and CARZ-N control dampers.

The functionality and performance of the entire filtration system were confirmed by several warranty measurements and tests, which mainly monitored the performance of filtration at the chimney outlet, dust in the working environment of a rough sorting plant, and noise emissions. All under the supervision of state authorities.