The subject of the work is the supply and installation of structures and equipment as a part of a complete reconstruction or construction of a new Neutralization and decontamination station NDS6.

The main technological parameters of the NDS6 technology after the implementation of works:

- The processed volume of solutions is 330 – 430 m3 /hour, the concentration of contaminants (dissolved substances) in the input solutions is about 11 g/l.

- The technology makes it possible to process and subsequently discharge up to 3 153 000 m3 of treated water per year into the watercourse.

- The production of the filter cake is 90 000 m3 /year, and the amount of discharged contaminants is about 23 000 tons / year, from 2018 to 2037 a total of about 400 thousand.

The scope of work is as follows:

- Complete delivery and assembly of steel structures incl. anchoring, processing of production drawing documentation, surface treatment, connecting material, means of assembly, cleaning and disposal of waste after finishing of the works, submission of samples of individual materials, construction site device cost, costs of media and lighting, costs of acceptances and tests, Health and Safety and Fire Fighting management, coordination of work with other suppliers, documents for approval and transfers. The total range of supplied steel structures in all affected buildings is more than 758 tons.

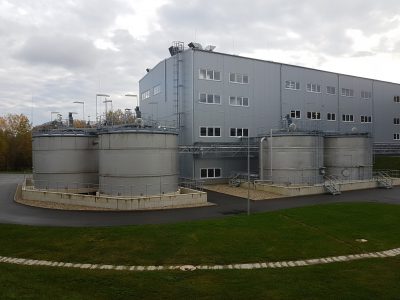

- Delivery and installation of stainless steel tanks H501, A502, A503, A504, A505, A506. The subject of the work includes production, materials, supplies, assembly, and testing of equipment. The tanks are supplied in material 1.4404. Dimensions are ø 8 300 mm at height 6 300 mm (A502-506) and ø 5 400 mm at height 5320 mm (H501).

- Structure, manufacture, and supply of mixing devices (propeller mixers including heating coils, slow-running mixers, etc. with dimensions for tanks up to ø 8 300 mm). The total number of delivered devices is 25 pcs.

- Delivery, complete assembly and testing of pipelines on operational sets PS01-12, including all fittings, seals, and flanges – material specification S235 and 1.4404.

- Delivery of 35 pcs of pumps and one automatic pressure station (ATS) manufactured by KSB Pumpy and Verder incl. assembly supervision of and commissioning.