The device is suitable for securing the operating supply of loose materials and transporting them further into the process – coal, biomass, crushed alternative fuels, gypsum, limestone, pellets, gravel sand, fertilizers, crushed municipal waste and other generally difficult to handle materials.

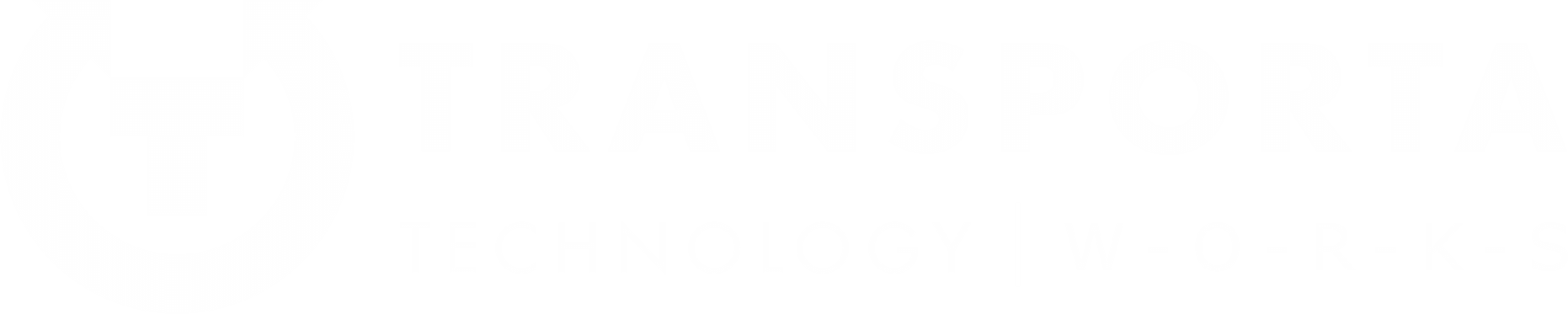

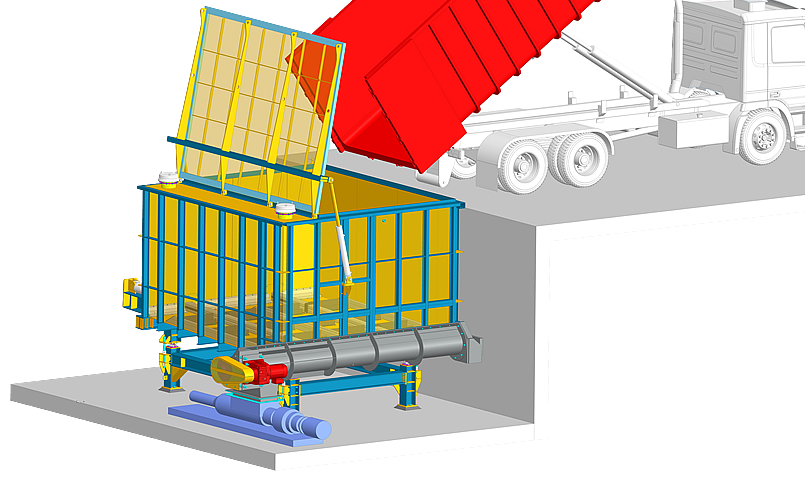

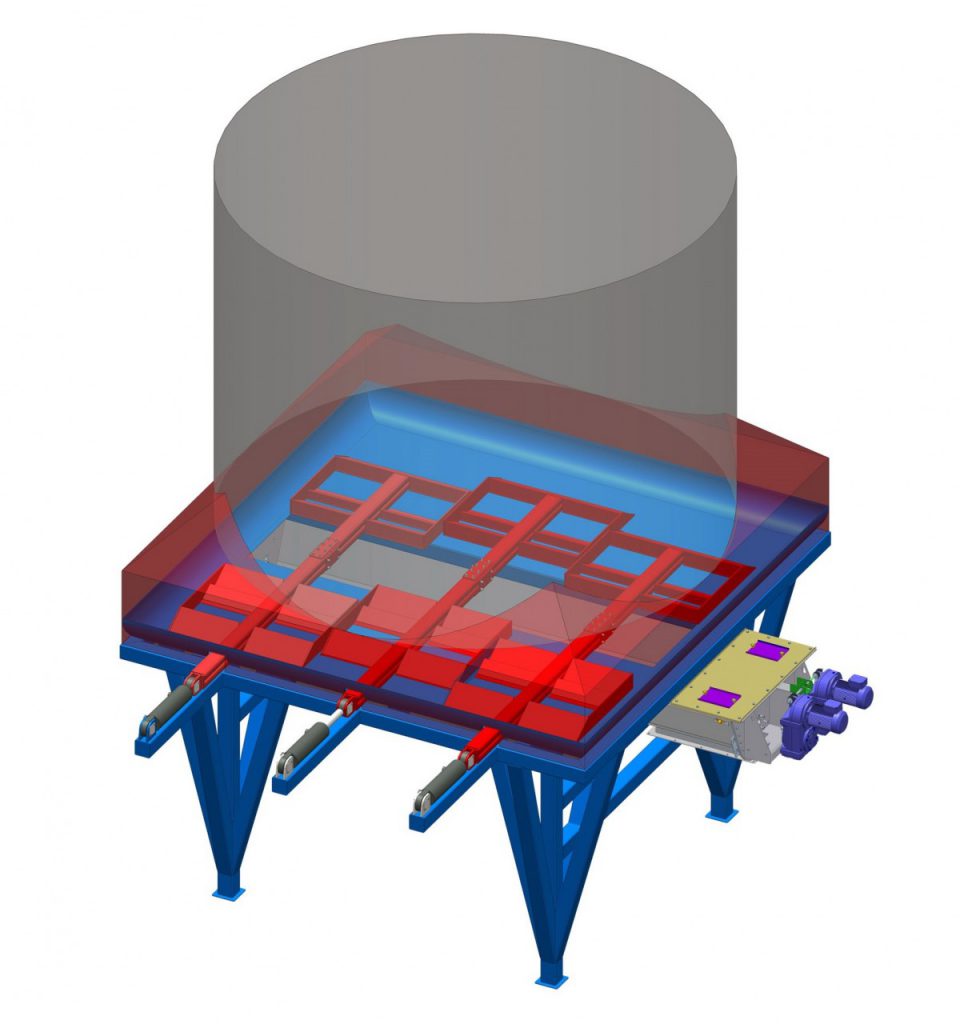

The device structurally consists of the container itself (cylindrical or “angular” – cube, block …), an activator (hydraulic, mechanical or pneumatic) and a regulated discharge conveyor (screw, rake …). The assembly is designed for the required volume and material characteristics.

The advantage of the device is a design variability, a possibility of redundancy of the device in order to support reliability, an adjustable range of transported material, a compact and robust design, and others. The device can be fully sealed and operated under overpressure, dust and odor can be extracted.

The offer includes design, production, delivery, assembly and commissioning according to the basic parameters specified by the customer. The design of the device and its static calculation corresponds to the specific requirements of the customer.

All products are subject to strict output controls in accordance with the quality requirements of TRANSPORTA Technology L.t.d

TRANSPORT PERFORMANCE:

- dosing performance 0 -500 m3/h

BASIC PARAMETERS:

- silo capacity 1 000 m3 or bigger based on requirements

VARIATIONS AND OPTIONS:

- hydraulic drive of moving silo bottom

- with a material outlet in the center or on the side of the silo

- continuous dosing by screws to the scale

- semiautomatic control

- weighed silo

ACCESSORIES:

- overpressure or underpressure flaps

- inerting and extinguishing equipment

- positioning sensors and rotation sensors of the discharge device

- hydraulic actuator

- control and inspection openings

Surface design corresponds to the needs of the conveyor location environment and the type of transported material. The device is supplied in stainless steel or with surface treatment for the particular environment.