We offer air cleaning systems as a part of our material transport projects or as separate EPC projects. We focus on air filtration systems in many ways at different points in the production process:

- Energy (power plants, heating plants, boiler rooms, waste incineration plants)

- Engineering industry (coke plants, ironworks, foundries, steelworks)

- Food industry (sugar production plants, etc.)

- Processing of raw materials (mining of limestone, coal, stone)

- Woodworking and furniture industry

- Paper industry

- Industrial vacuum cleaners – stationary and mobile

- Overhaul and modernization of filtration equipment

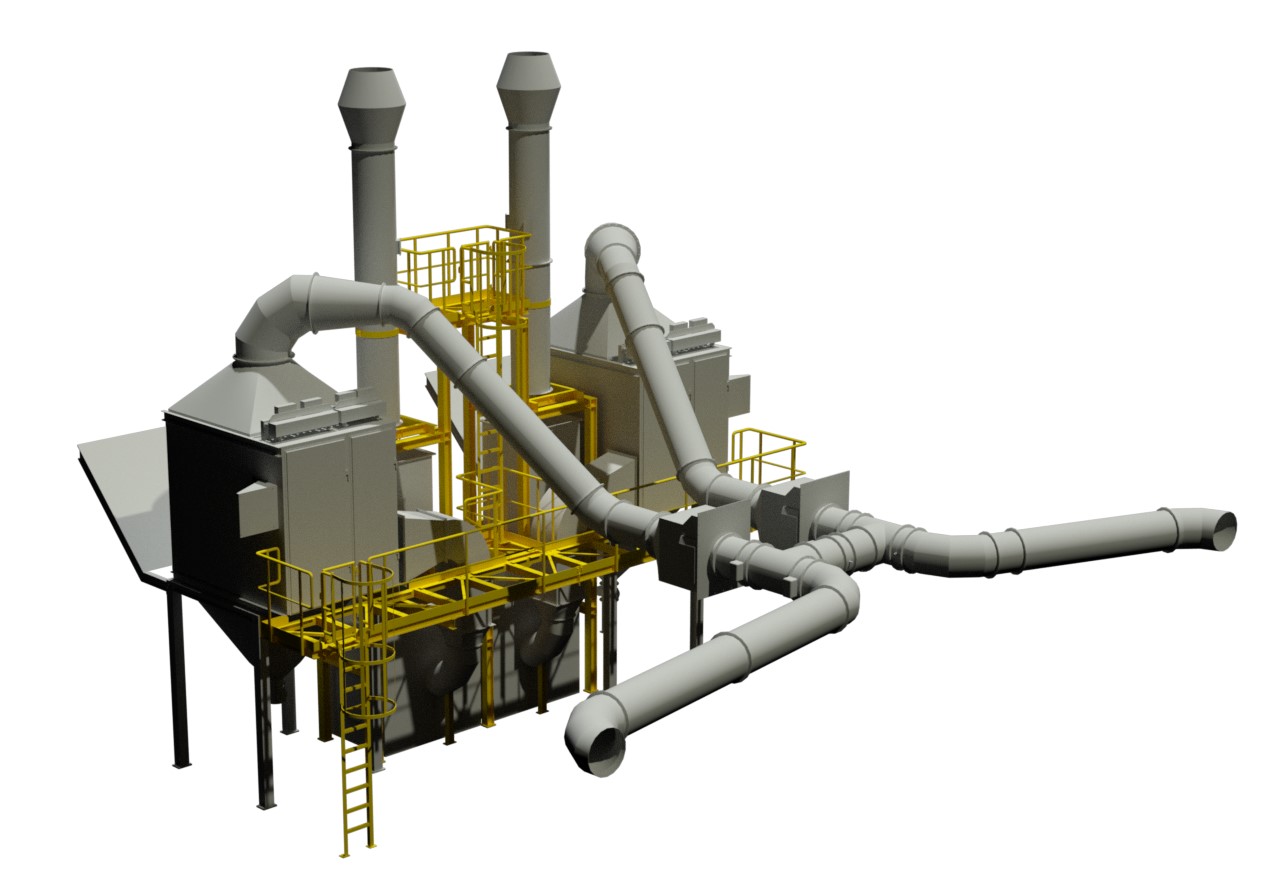

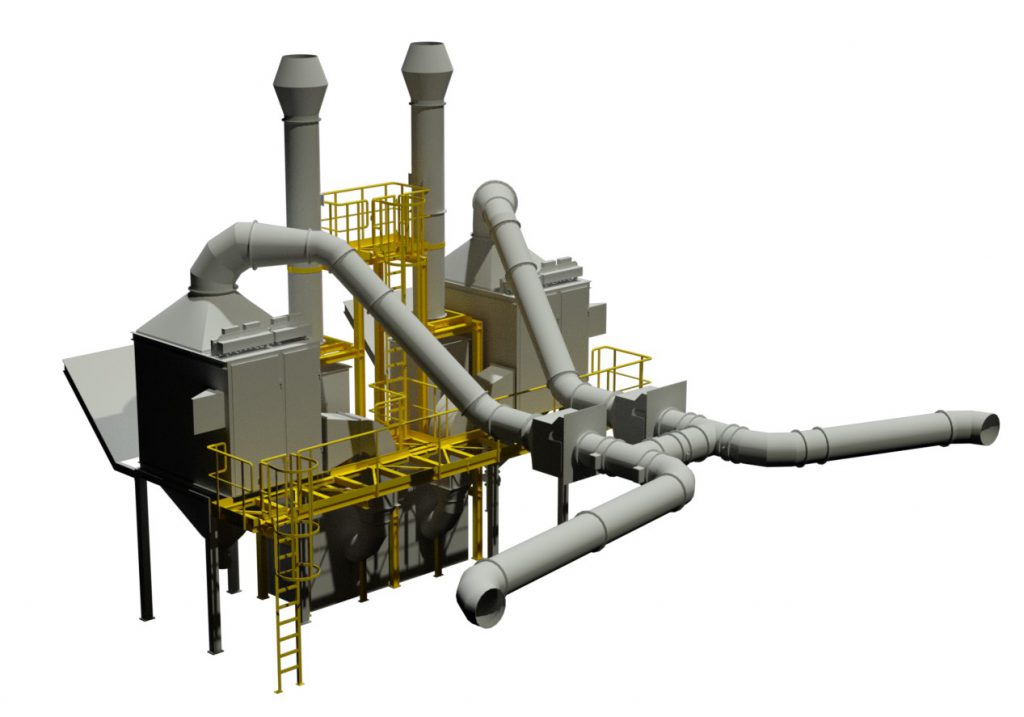

Filtration devices based on the principle of mechanical filtration of air and flue gases are physically simple and often technically complex. It is not decisive whether these are filters of solid dust particles or whether they are filters of gases and aerosols, these devices are always based on a complex set of certain mechanisms and components that ensure their required function.

High-quality filter units with controlled regeneration with a connection to the discharge of clean flue gases or air free of solid pollutants (dust) are the basis.

Types of filtration equipment:

- Industrial filters

– Fabric filters with flat or round filter element (bag), with regeneration by compressed air pulse jet or backwash

– Cartridge filters

– Ceramic filters - Dry mechanical separator – cyclones and multicyclones

- Wet mechanical separators – scrubbers

- Electrostatic and hybrid filters

- Desulphurisation and reduction of gaseous pollutants – removal of SOx, NOx, PCDD, PCDF, VOC

Standard air, smoke and flue gases cleaning project usually contains the following basic elements of the set:

- Installation of filter units incl. monitoring the control and filling of the dust tank

- Installation of sorbent dosing device incl. piping and silos, if necessary

- Installation of compressed air pipelines for filter regeneration and control of drives and sensors

- Noise reduction measures – fan noise cover incl. silencer on the outlet pipe

- System of control and closing flaps – mechanically, electrically or pneumatically operated

- Anti-explosion system in case of operation of the device in the environment with ATEX zone – safety check valves for Carz type pipes, protection of the filter device based on the principle of anti-explosion diaphragm valves

- Complete inlet (suction) and outlet pipes incl. insulation and cover, if necessary

- Rotary valve for further transport

- Installation of pipes for extinguishing in case of equipment fire incl. automatic extinguishing system and detection in case of extraction of flammable dusts and vapors

- Complete supporting steel structures

- Exhaust system and transport of dust or desulphurization products incl. storage facilities and silos

- ID fan controlled by frequency converter or without