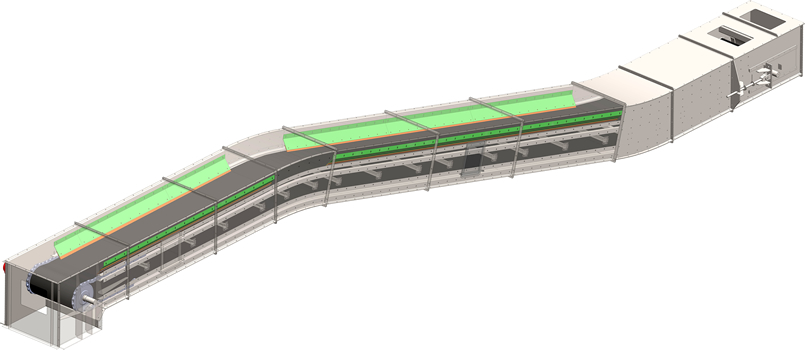

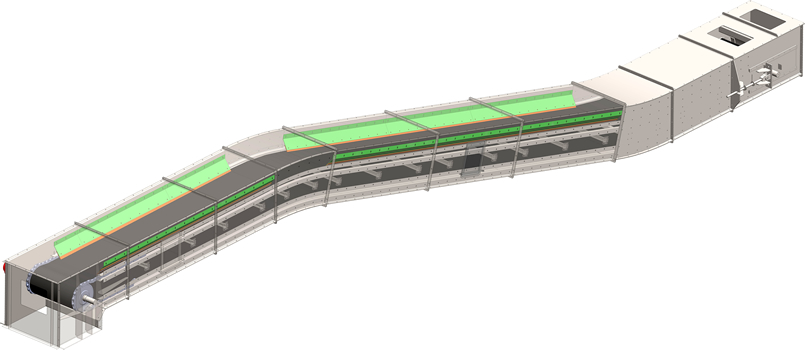

The device is suitable for the transport of loose materials – coal, biomass, crushed alternative fuels, gypsum, limestone, pellets, gravel sand, fertilizers, crushed municipal waste, and others.

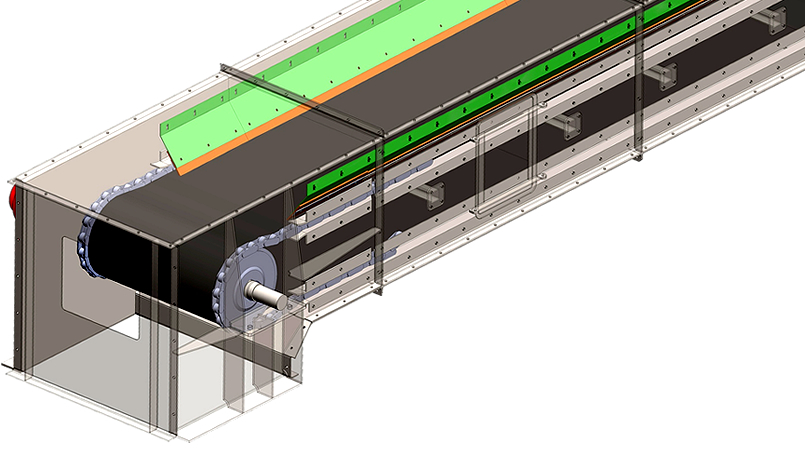

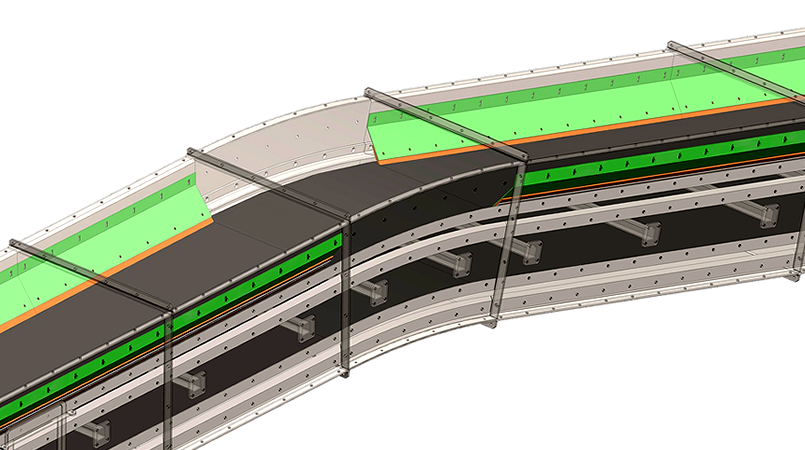

The basic technical solution of this conveyor consists in using a chain for transfer of tensile forces and a rubber belt as a carrier of the transported material – the material is carried on the belt.

The conveyor can change elevation in relatively small radii, it can be completely covered, dust and odor can be filtered and the lower branch of the conveyor cleans itself. A great advantage is significantly lower abrasion of the conveyor body compared to common chain conveyors and also the power input required for material transport.

The entire conveyor is designed as a modular kit with a given installation height. The transport speed and conveyor width are then changed according to the required transport capacity.

The offer includes design, production, delivery, assembly and commissioning according to the basic parameters specified by the customer. The design of the device and its static calculation corresponds to the specific requirements of the customer.

All products are subject to strict output controls in accordance with the quality requirements of TRANSPORTA Technology L.t.d

TRANSPORT PERFORMANCE:

- 5 – 200 t/h (up to approx. 200 m3)

BASIC PARAMETERS:

- belt width: 400 – 1 400 mm

- belt speed up to 1 m/s

- length up to 50 m

VARIATIONS AND OPTIONS:

- a possible design for low operating temperatures (creeping drives)

- self-supporting construction

- oil-resistant conveyor belts

ACCESSORIES:

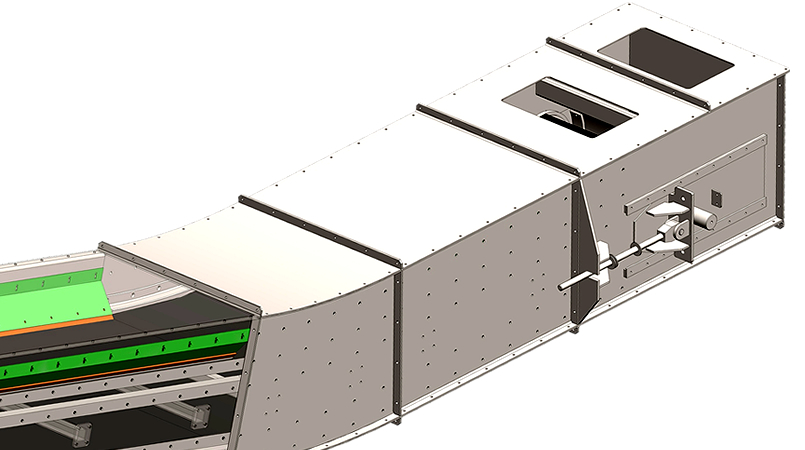

- hopper – chute

- design with coverings to prevent dustiness and noise

- control and inspection openings

- footbridges

- safety and control elements – cable stop, rotation sensors, stop buttons

Surface design corresponds to the needs of the conveyor location environment and the type of transported material. The device is supplied in stainless steel or with surface treatment for the particular environment.