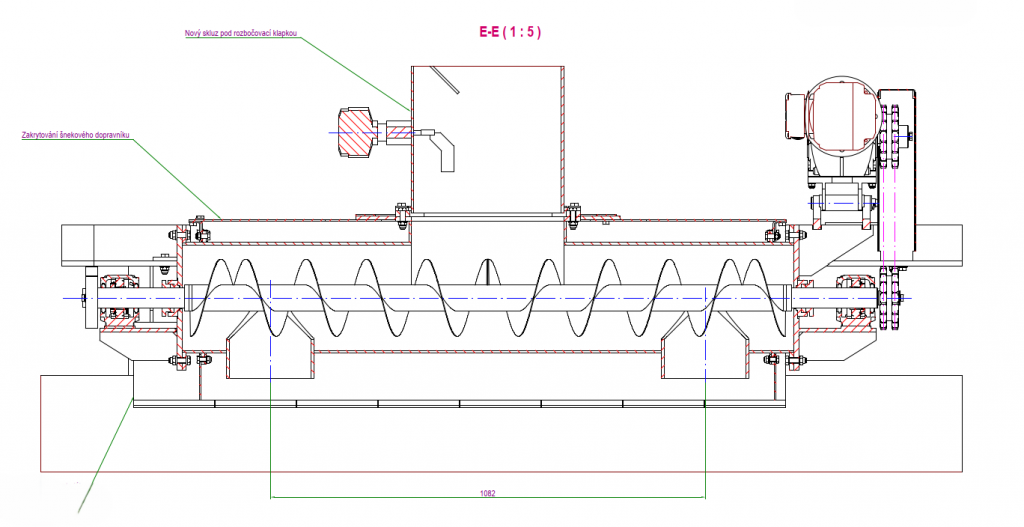

This conveyor is suitable for transporting all types of bulk material. The main advantage of this conveyor against a conventional belt conveyor is that the conveyor belt behind the material hopper forms into a circular shape, allowing the belt to turn both horizontally and vertically. While respecting geometric rules, this allows for a flexible route between the feed and discharge points, avoiding transfer points and reducing dust and noise emissions. Since the material is enclosed in the belt, it cannot escape into the surrounding environment and is also protected from the external environment, e.g., rain.

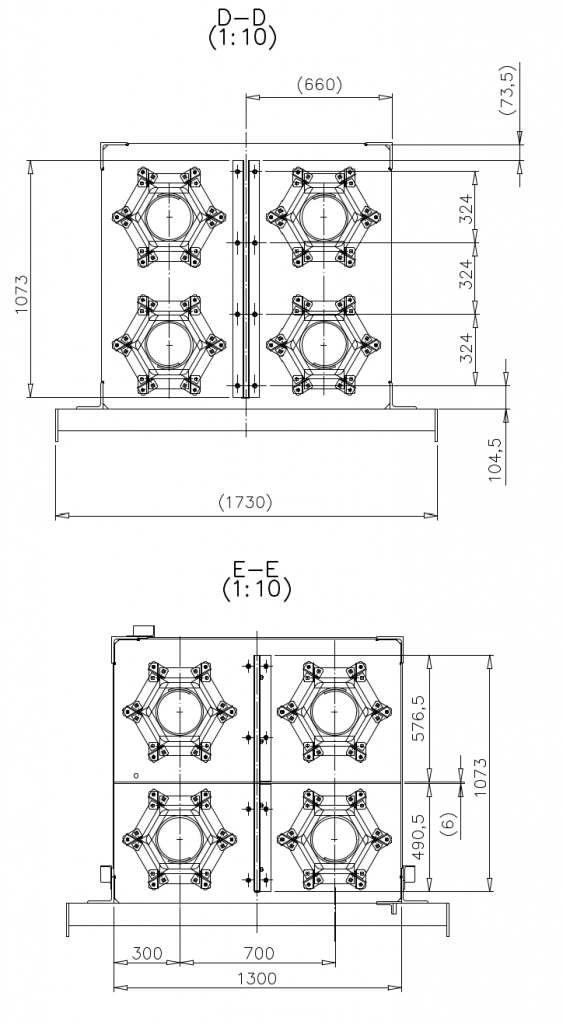

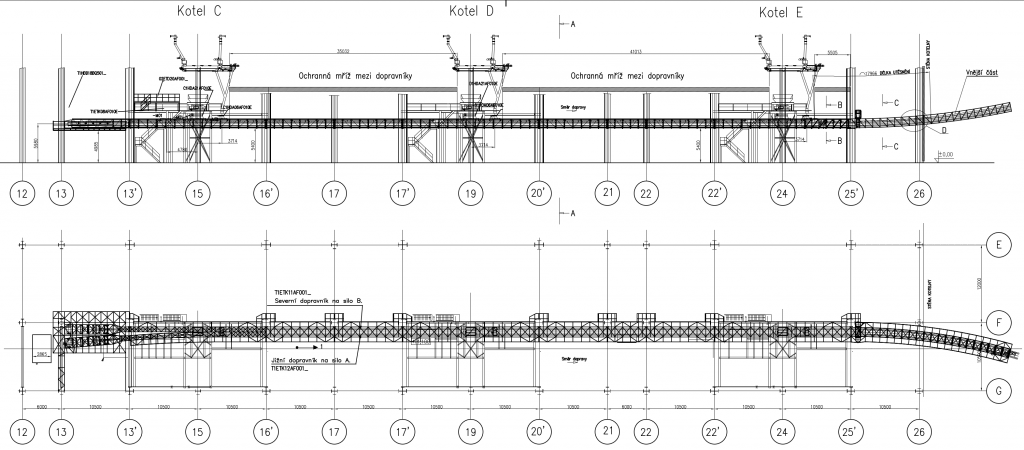

The conveyor stations are similar to those of a conventional belt conveyor. However, the design of the conveyor frames differs significantly, as the pipe conveyor usually has a self-supporting structure with an integrated walkway. For large support spans (approximately over 40 m), the conveyor must be installed in a supporting bridge.

TRANSPORT CAPACITY:

- up to 2000 m3/hour

BASIC PARAMETERS:

- belt width from 600 to 2000 mm (from PC150 to PC500)

- belt speed up to 5 m/s (depending on belt width and conveyed material)

- length from 30 m to 10 km

- material grain size up to 1/3 of the conveyor belt diameter

OPTIONAL SOLUTIONS:

- both-directional material transport

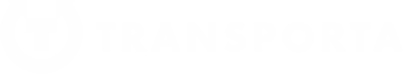

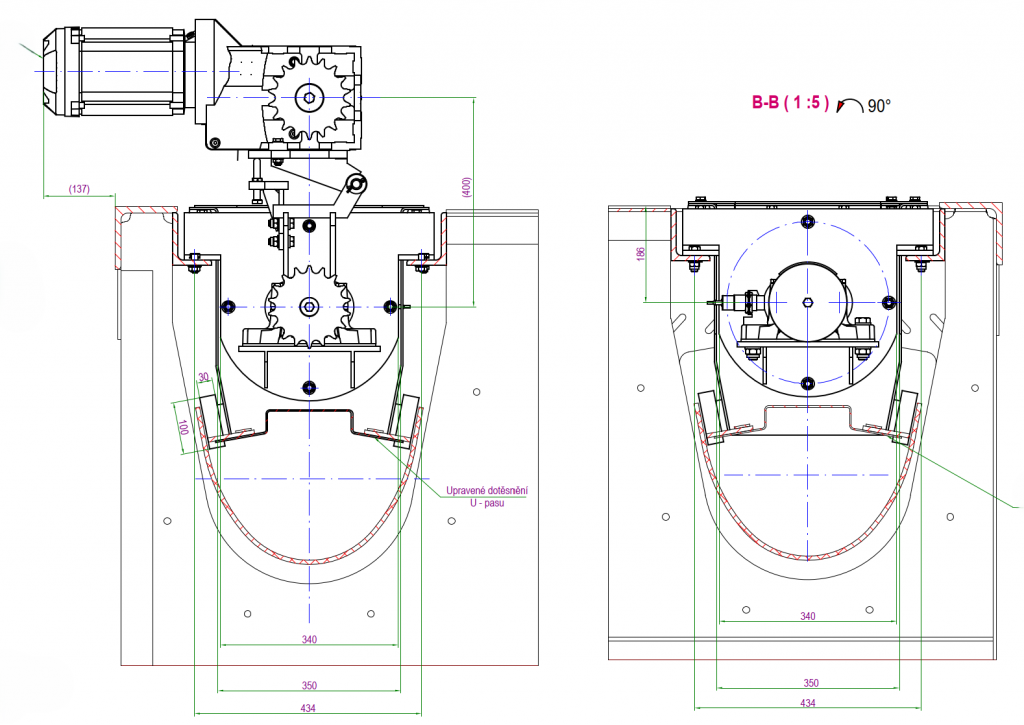

- U-conveyor for increased transport capacity

ACCESSORIES:

- belt scrapers

- material weighing

- hopper – discharge chute – slide

- various types of conveyor covers

- design with low-noise idlers

- magnetic and mechanical separators

- impact bed

- safety and control elements – pull cord switch, speed sensors, belt misalignment switches, stop buttons

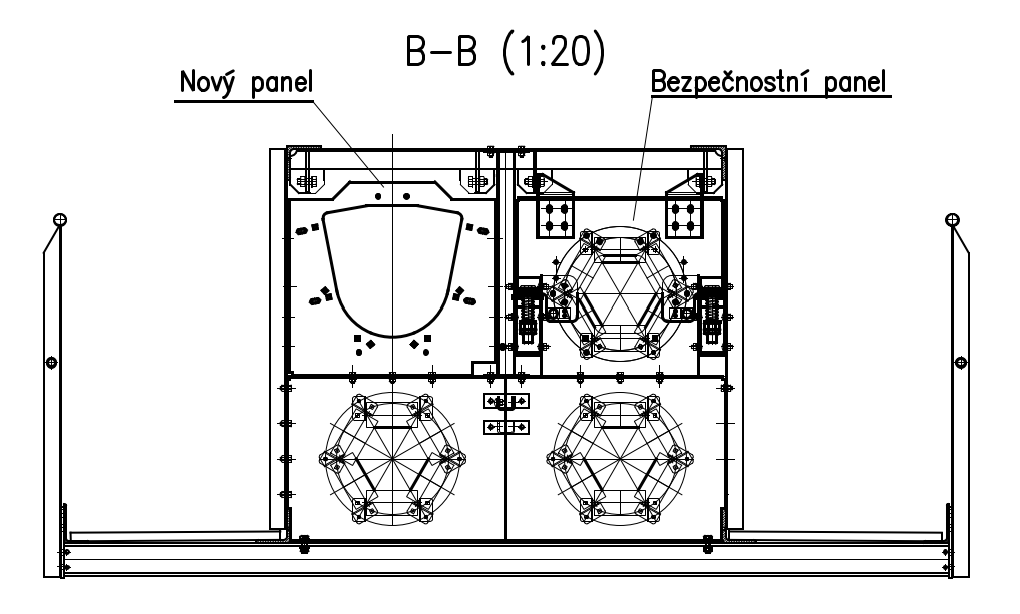

- safety panels preventing damage to the conveyor due to material overload

The offer includes design, production, delivery, assembly and commissioning according to the basic parameters specified by the customer. The design of the device and its static calculation corresponds to the specific requirements of the customer.

All products are subject to strict output controls in accordance with the quality requirements of TRANSPORTA.

Surface design corresponds to the needs of the conveyor location environment and the type of transported material. The device is supplied in stainless steel or with surface treatment for the particular environment.

23036 ČEZ EPR Dedusting of KOCH conveyors

23001Z ČEZ ELE safety guards for slag conveyor

22028Z U-conveyor – rebuilding pipe conveyor for higher capacity in the power plant Prunéřov