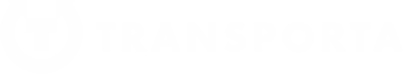

Tensioning is used as an independent product in assemblies or transport devices, e.g. belt and pipe conveyors, elevators.

Rope tensioning is used in transport devices where it is not possible to use classical gravity tensioning of the conveyor belt or where it is necessary to change the tensioning force more often until it is completely released e.g. for maintenance reason.

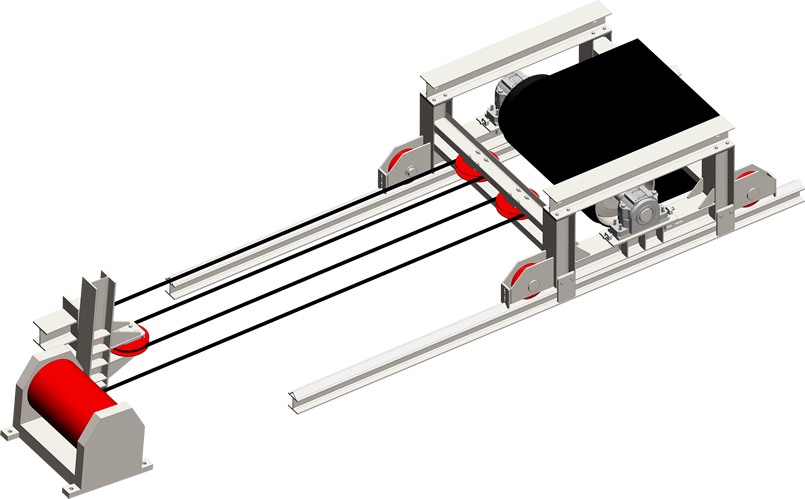

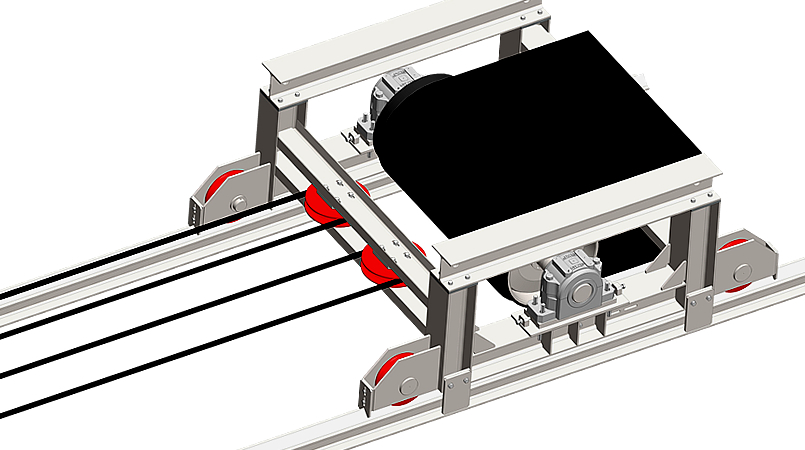

The rope tensioning consists of a strain gauge device for tension measuring, brake, drive, winch and control system. The device continuously keeps the tension value in the required range. The given value is tensometrically detected. In the idle state of tensioning, the force is held by the drive brake, even in the event of a voltage drop.

The offer includes design, production, delivery, assembly and commissioning according to the basic parameters specified by the customer. The design of the device and its static calculation corresponds to the specific requirements of the customer.

All products are subject to strict output controls in accordance with the quality requirements of TRANSPORTA Technology L.t.d

BASIC PARAMETERS:

- tensioning length 120 m

- tensioning force up to 600 kN

VARIATIONS AND OPTIONS:

- electric or hydraulic drive

ACCESSORIES:

- control panel – visualization

- end switches of a winch

- hydraulic unit

Surface design corresponds to the needs of the conveyor location environment and the type of transported material. The device is supplied in stainless steel or with surface treatment for the particular environment.