The device is suitable for the transport of loose materials – coal, slag, biomass, crushed alternative fuels, gypsum, limestone, pellets, gravel sand, fertilizers, crushed municipal waste, and others.

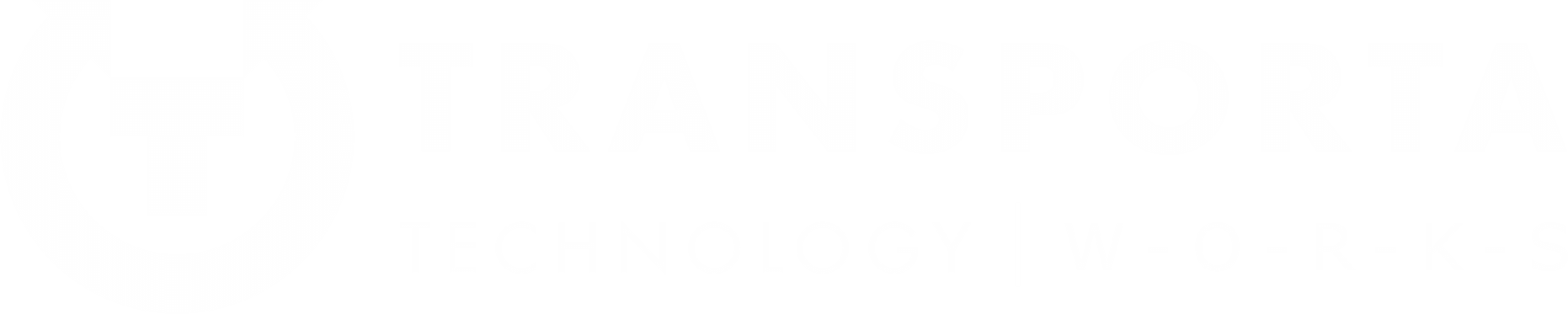

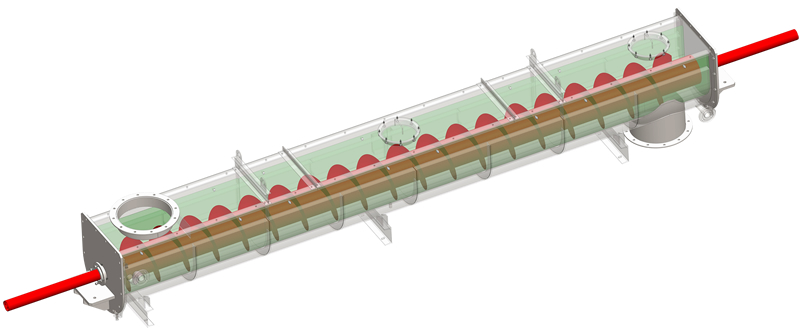

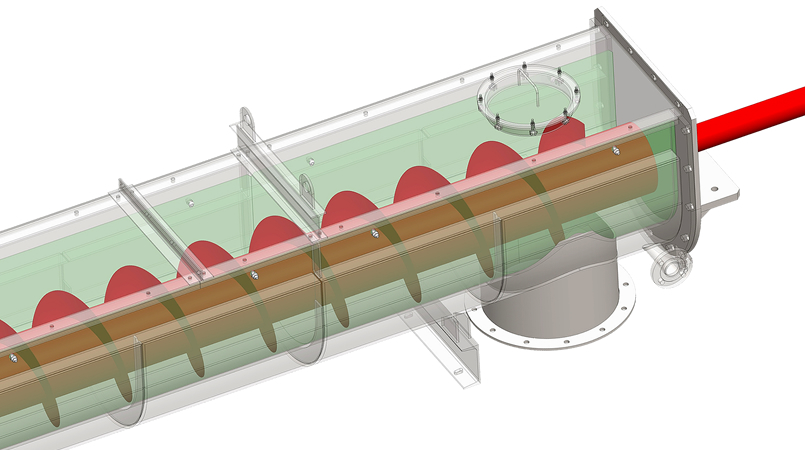

The device is used for transport of a small-grained material by rotation of the helical screw blade in the axis of the conveyor. Material cooling takes place during this transport the device works as a heat exchanger. Heat exchange occurs in the body of the conveyor where the material to be cooled transfers heat through the conveyor walls to a cooling medium.

The conveyors are used to cool the material in production processes where the temperature of the transported material needs to be steeply quenched.

The offer includes design, production, delivery, assembly and commissioning according to the basic parameters specified by the customer. The design of the device and its static calculation corresponds to the specific requirements of the customer.

All products are subject to strict output controls in accordance with the quality requirements of TRANSPORTA Technology L.t.d

TRANSPORT PERFORMANCE:

- 15-25 t/h (depending on temperature gradient)

BASIC PARAMETERS:

- diameter 150 – 800 mm

- length 12 m

VARIANTIONS AND OPTIONS:

- multi-shaft / multi-screw design

- continuous weighing of dosing

- hardened welds on screw leaves

- design in a trough or circular cross-section

ACCESSORIES:

- hopper – chute

- control and inspection openings

- safety and control elements – cable stop, rotation sensors, stop buttons

- temperature sensors

Surface design corresponds to the needs of the conveyor location environment and the type of transported material. The device is supplied in stainless steel or with surface treatment for the particular environment.