The equipment is suitable for transport of loose materials – coal, biomass, crushed alternative fuels, gypsum, limestone, pellets, gravel sand, fertilizers, crushed municipal waste and others.

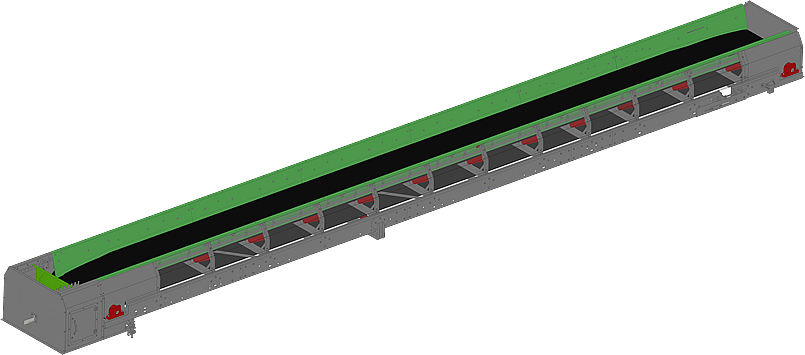

The supporting structure consists of bent sheet metal profiles into which rollers are placed, which form the travel path for the rubber belt. The rubber belt is tensioned in the loop between the conveyor drums. The material is transported on this belt – the material is carried on the belt.

This type of conveyor is mainly used in shorter distance technological operations with lower transport capacity requirements. This design of the conveyor allows lower installation dimensions and reduces the weight of the device itself. Thanks to the simple construction design and the principle of material transport, the conveyor has a long lifetime.

The entire conveyor is designed as a modular kit with the use of standard components. The advantages are low operating and service costs.

The offer includes design, production, delivery, assembly and commissioning according to the basic parameters specified by the customer. The design of the equipment and its static calculation correspond to the specific requirements of the customer.

All products are subject to strict output controls in accordance with the quality requirements of TRANSPORTA Technology L.t.d

TRANSPORT PERFORMANCE:

- 5 -700 t/h (up to approx. 700 m3)

BASIC PARAMETERS:

- belt width: 400 – 1 400 mm

- belt speed up to 3 m/s

- length up to 2 000 m

VARIANTIONS AND OPTIONS:

- reverse design (bidirectional transport)

- gravitational, mechanical, electrical or hydraulic

- conveyor belt tensioning

- with a moveable hopper

- mobile design (moveable conveyor)

- position sensing

- placement on a surface, on a steel structure or self-supporting

- a possible design for low operating temperatures (creeping drives)

- oil-resistant conveyor belts

ACCESSORIES:

- wipers

- material weighing

- hopper – chute

- coverings to prevent dustiness

- inspection and inspection openings

- magnetic and mechanical separators

- footbridges

- safety and control elements: cable stop, speed sensors, belt misaligning sensors, stop buttons

Surface design corresponds to the needs of the conveyor location environment and the type of transported material. The device is supplied in stainless steel or with surface treatment for the particular environment.