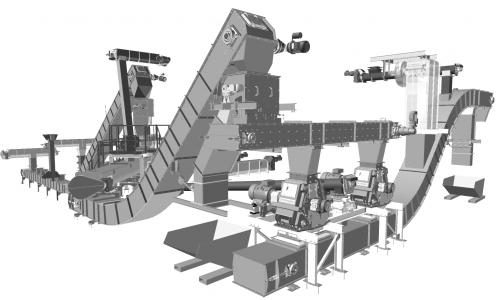

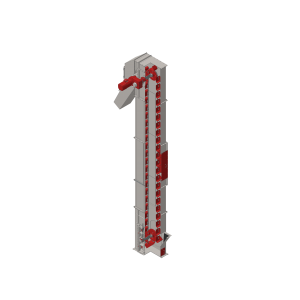

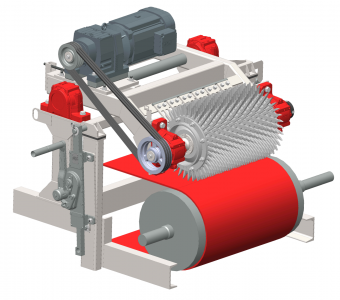

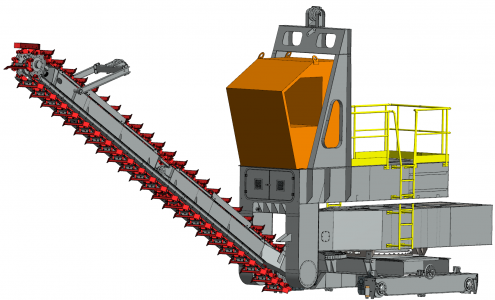

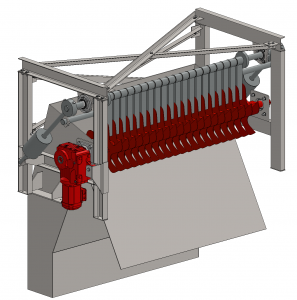

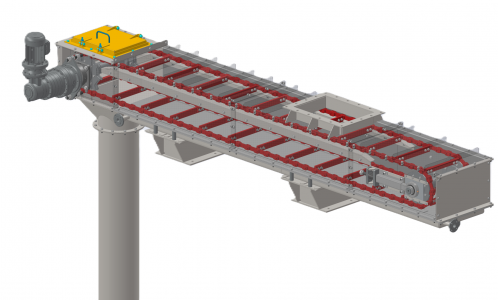

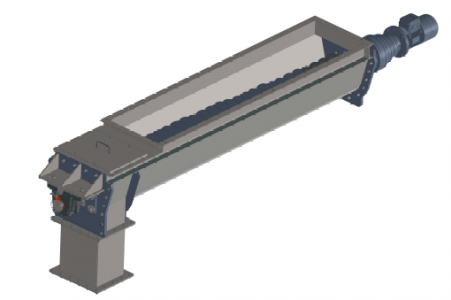

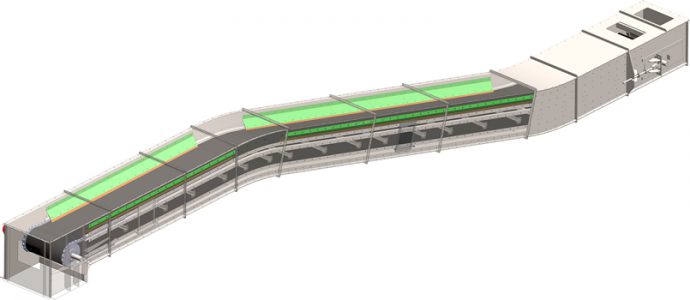

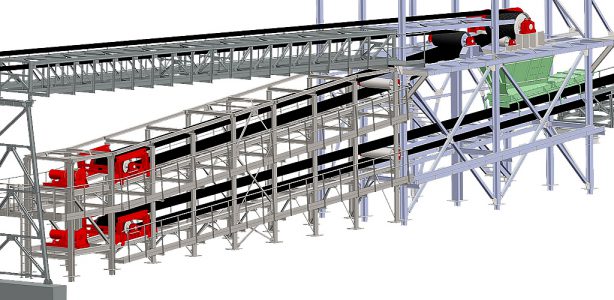

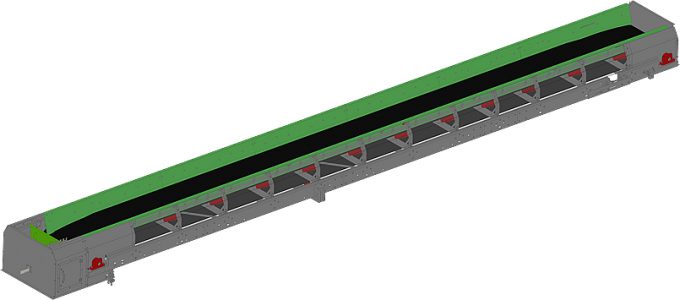

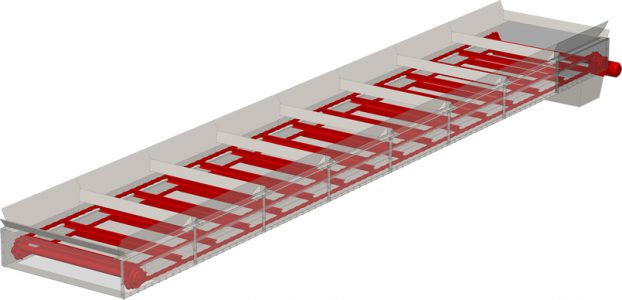

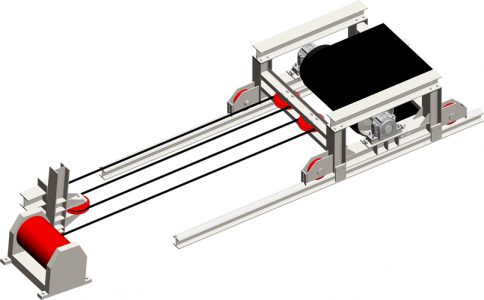

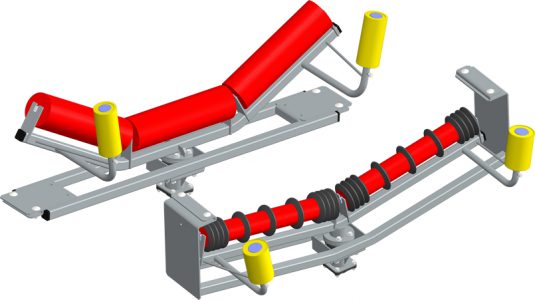

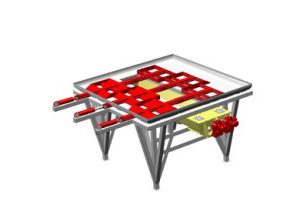

This conveyor is suitable for transporting all types of bulk material. The main advantage of this conveyor against a conventional belt conveyor is that the conveyor belt behind the material hopper forms into a circular shape, allowing the belt to turn both horizontally and vertically. While respecting geometric rules, this allows for a flexible route […]

More..