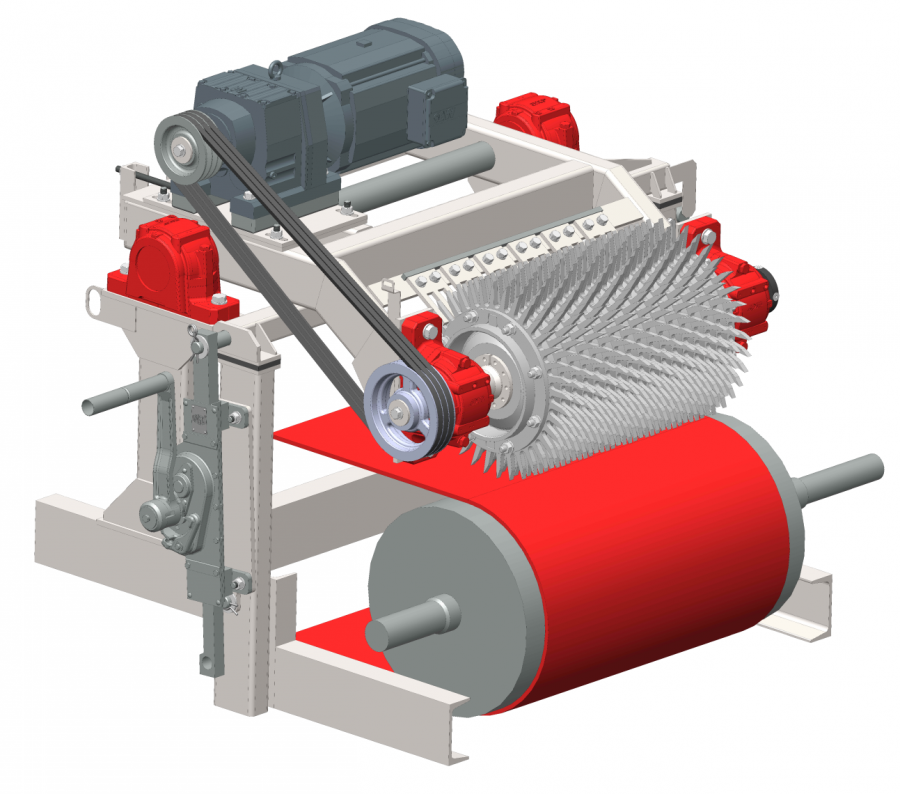

The disintegrator ensures the desired granularity/coarseness of the transported material. It is placed on the drive drum of the belt conveyor.

This device is a suitable component in a technological system where there may be cases of the transported material hardening or sticking together. The disintegrator is a part of the belt conveyor and can be installed in existing systems without major structural modifications. The disintegrator must not function as a material crusher.

The drum with the stars is positioned above the drive drum, with the tips of the stars set against the drum/conveyor belt. The stars are the functional element of the disintegrator, breaking up material that exceeds the desired granularity, which is defined by the distance between the belt and the disintegrator.

The swing arm holds the disintegrator drum at the required height above the drive drum in the working position. The arm is motion-free and balanced to lift when a solid object enters, preventing damage to the conveyor belt.

The drive rotates the disintegrator drum through a belt transmission. The drive is mounted on the swing arm and can serve as a weight/counterweight depending on the specific installation. A manual lifting mechanism allows for the deactivation of the disintegrator.

All products undergo strict final inspections by the quality requirements of TRANSPORTA Technology s.r.o.

The device consists of five main parts:

· drum

· crushing star assembly

· swing arm with counterweight

· drive

· lifting mechanism

Parameters for Determining the Device Design:

· hardness/cohesiveness of the material

· amount of the transported material, including an estimate of the percentage of oversized pieces

· load-bearing capacity of steel structures (which can be assessed by an inspection of a technician from TRANSPORTA Technology)

· belt speed and other conveyor parameters