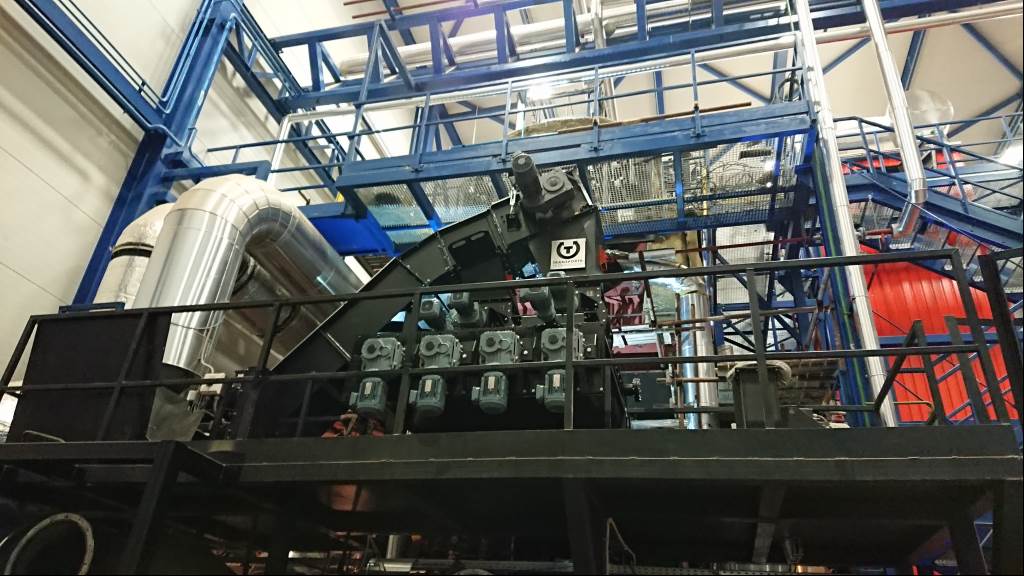

We offer a system for transporting fuel to the boiler based on our experience and the development of the fuel base in recent years. It includes a portfolio of fuels – brown coal, biomass and transport for waste incineration.

The transport system is individually designed according to the customer’s layout requirements and the quantity and type of fuel. A complete solution usually i ncludes:

· Fuel unloading at the interim storage (with the possibility of homogenization)

· Fuel feeding into the transport route (screw conveyors or screw fields, moving floors, hoppers)

· Sorting, crushing and other treatments (rotary or vibrating screens, crushers)

· External transport route (belt and chain conveyors, screw conveyors)

· Operating storage containers

· Feeding and weighing (solved by inserted scales, strain gauge weighing of the storage container, and volumetric feeding)

· Internal transport route (chain and belt conveyors, screw conveyor feeding)

· Possibility of installing sealing air and local extraction of conveyors along the route inside the boiler room to reduce dustiness

The offer includes design, production, delivery, installation and commissioning according to the basic parameters specified by the customer.

The design of all equipment meets the specific requirements of the customer. All products are subject to strict output controls based on the quality requirements of TRANSPORTA Technology s.r.o.

The surface treatment corresponds to the environmental needs, the location of the conveyor and the type of material transported material.

The technical solution is designed by a technologist, from the conceptual solution to the final implementation documentation. Subsequently, as part of the implementation, we provide installation and commissioning with our capacities and partially manufacture individual system components. We then focus on service work and inspection of the equipment within the warranty period.