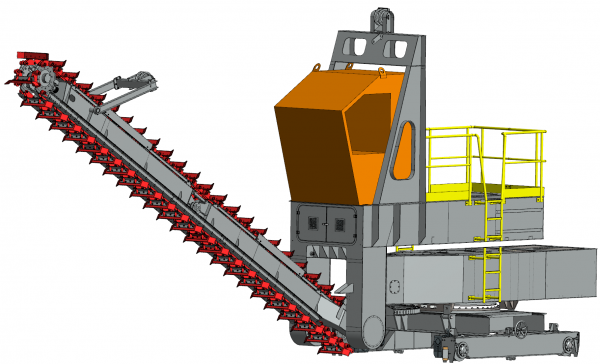

The excavator machine is used for reclaiming bulk material from a stockpile by raking the material underneath the machine onto the subsequent conveyor belt.

The machine consists of five main parts – chassis, lower structure, upper structure, arm, and operator cabin. The chassis is equipped with four electric motors, each driving one of the machine’s traction wheels. The lower structure is mounted on the chassis via bearings and can rotate 180°, allowing the machine to rake in both directions. The upper structure is mounted on the lower structure via a shaft and can rotate approximately 175° (depending on the dimensions of the storage). The arm with a chain conveyor (reclaimer) is mounted on the upper structure, which rakes the material underneath the machine.

The stockpile machine is operated locally from an air-conditioned cabin by the operator. The operator has the option to use an automatic mode. The machine is then controlled by a PLC program and the operator supervises its operation.

As a part of our delivery, we provide the design of the optimal solution for your storage and material, as well as the project, manufacturing, delivery, assembly, and commissioning according to specified parameters.

The surface treatment of the machine meets the environmental requirements of its location and the type of material. The machine structure is supplied in stainless steel or with surface treatment suitable for the environment. The active components of the chain conveyor, rakes, are made of highly abrasion-resistant steel.

All products undergo strict final inspections following the quality requirements of TRANSPORTA Technology s.r.o.

TRANSPORT CAPACITY

· 40 – 140 t/h

ACCESSORIES

· camera system for monitoring machine operation

· material unloading system under the machine

BASIC PARAMETERS

· arm length: 6 000 – 13 000 mm